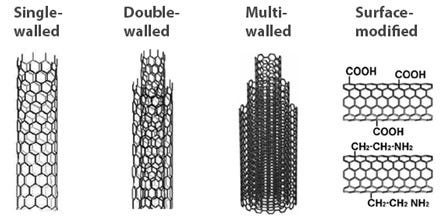

Their unique composition, geometry, and properties enable numerous potential carbon nanotubes applications. Getting costs down to commercially viable levels has proven challenging but increasing scale is happening.

The special nature of carbon combines with the molecular perfection of single-wall CNTs to endow them with exceptional material properties, such as very high electrical and thermal conductivity, strength, stiffness, and toughness.

No other element in the periodic table bonds to itself in an extended network with the strength of the carbon-carbon bond. The delocalized pi-electron donated by each atom is free to move about the entire structure, rather than remain with its donor atom, giving rise to the first known molecule with metallic-type electrical conductivity. Furthermore, the high-frequency carbon-carbon bond vibrations provide an intrinsic thermal conductivity higher than even diamond.

In most materials, however, the actual observed material properties – strength, electrical conductivity, etc. – are degraded very substantially by the occurrence of defects in their structure. For example, high-strength steel typically fails at only about 1% of its theoretical breaking strength. CNTs, however, achieve values very close to their theoretical limits because of their molecular perfection of structure.

This aspect is part of the unique story of CNTs. CNTs are an example of true nanotechnology: they are only about a nanometer in diameter, but are molecules that can be manipulated chemically and physically in very useful ways. They openned an incredible range of applications in materials science, electronics, chemical processing, energy management, and many other fields.

Energy Storage

CNTs have the intrinsic characteristics desired in material used as electrodes in batteries and capacitors, two technologies of rapidly increasing importance. CNTs have a tremendously high surface area (~1000 m2/g!!), good electrical conductivity, and very importantly, their linear geometry makes their surface highly accessible to the electrolyte.

Research has shown that CNTs have the highest reversible capacity of any carbon material for use in lithium-ion batteries [B. Gao, Chem. Phys. Lett. 327, 69 (2000)]. In addition, CNTs are outstanding materials for supercapacitor electrodes [R.Z. Ma, et al., Science in China Series E-Technological Sciences 43 178 (2000)] and are now being marketed for this application.

CNTs also have applications in a variety of fuel cell components. They have a number of properties, including high surface area and thermal conductivity, which make them useful as electrode catalyst supports in PEM fuel cells. They may also be used in gas diffusion layers, as well as current collectors, because of their high electrical conductivity.

CNTs’ high strength and toughness-to-weight characteristics may also prove valuable as part of composite components in fuel cells that are deployed in transport applications, where durability is extremely important.

The lithium-ion battery, which was originally pioneered in 1912 by G.N. Lewis but not made commercially available until the 1970s, is the fastest growing and most promising battery available today. With the greatest electrochemical potential and largest energy density in weight compared to all other metals, lithium-ion is a safe and low maintenance battery option for most electronics on the market today.

Lithium-ion batteries can be separated into three basic components: the two electrodes; the anode (negative electrode), the cathode (positive electrode) and an electrolyte allowing charged ions to flow between the electrodes enabling charge or discharge.

While lithium-ion has several advantages over most other chemistries available for energy storage, it is a fragile chemistry, requiring a protection circuit in order to maintain its safe operation.

Researchers are becoming increasingly interested in developing high-capacity lithium-ion batteries, particularly those with advanced flexibility to allow thin batteries to be incorporated into wearable devices.

Companies, such as Texas based Black Diamond Structures, are looking to incorporate current research on this topic into real-world topics. Through the application of groundbreaking nanotechnology, Black Diamond Structures has integrated nanomaterials into both lead acid and lithium-ion batteries, enabling enhanced energy storage, increased strength, and higher performance.

These batteries are both part of the MOLECULAR REBAR ® technology created by Black Diamond Structures, and they both specifically address the tendency of carbon nanotubes to become entangled, which is a plague of this powerful agent.

Through MOLECULAR REBAR ® products, carbon nanotubes are untangled into discrete individual tubes of a uniform size, allowing their successful incorporation into lead acid and lithium-ion batteries, creating significantly stronger and conductive energy storage products.

The lead acid batteries exhibit a 50% improved cycle life compared to its preceding products, improved cold temperature performance, a 25% improved charge-acceptance, and a stronger resistance to both physical and thermal misuse.

Molecular Electronics

The idea of building electronic circuits out of the essential building blocks of materials – molecules – has seen a revival the past five years, and is a key component of nanotechnology. In any electronic circuit, but particularly as dimensions shrink to the nanoscale, the interconnections between switches and other active devices become increasingly important.

Their geometry, electrical conductivity, and ability to be precisely derived, make CNTs the ideal candidates for the connections in molecular electronics. In addition, they have been demonstrated as switches themselves.

Thermal Materials

CNTs have extraordinary electrical conductivity, heat conductivity, and mechanical properties. They are probably the best electron field-emitter possible. They are polymers of pure carbon and can be reacted and manipulated using the well-known and tremendously rich chemistry of carbon.

This provides opportunity to modify their structure, and to optimize their solubility and dispersion. Very significantly, CNTs are molecularly perfect, which means that they are normally free of property-degrading flaws in the nanotube structure.

Their material properties can therefore approach closely the very high levels intrinsic to them. These extraordinary characteristics give CNTs potential in numerous applications.

The record-setting anisotropic thermal conductivity of CNTs is enabling many applications where heat needs to move from one place to another. Such an application is found in electronics, particularly advanced computing, where uncooled chips now routinely reach over 100oC.

The technology for creating aligned structures and ribbons of CNTs [D.Walters, et al., Chem. Phys. Lett. 338, 14 (2001)] is a step toward realizing incredibly efficient heat conduits. In addition, composites with CNTs have been shown to dramatically increase their bulk thermal conductivity, even at very small loadings.

Structural Materials

The superior properties of CNTs are not limited to electrical and thermal conductivities, but also include mechanical properties, such as stiffness, toughness, and strength. These properties lead to a wealth of applications exploiting them, including advanced composites requiring high values of one or more of these properties.

Electrical Emitters

CNTs are the best known field emitters of any material. This is understandable, given their high electrical conductivity, and the incredible sharpness of their tip (because the smaller the tip’s radius of curvature, the more concentrated will be an electric field, leading to increased field emission; this is the same reason lightning rods are sharp).

The sharpness of the tip also means that they emit at especially low voltage, an important fact for building low-power electrical devices that utilize this feature. CNTs can carry an astonishingly high current density, possibly as high as 1013 A/cm2. Furthermore, the current is extremely stable.

An immediate application of this behavior receiving considerable interest is in field-emission flat-panel displays. Instead of a single electron gun, as in a traditional cathode ray tube display, in CNT-based displays there is a separate electron gun (or even many of them) for each individual pixel in the display.

Their high current density, low turn-on and operating voltages, and steady, long-lived behavior make CNTs very attractive field emitters in this application. Other applications utilizing the field-emission characteristics of CNTs include general types of low-voltage cold-cathode lighting sources, lightning arrestors, and electron microscope sources. [B.Q. Wei, et al, Appl. Phys. Lett. 79 1172 (2001)].

Fabrics And Fibers

Fibers spun of pure CNTs have recently been demonstrated [R.H. Baughman, Science 290, 1310 (2000)] and are undergoing rapid development, along with CNT composite fibers. Such super strong fibers will have many applications including body and vehicle armor, transmission line cables, woven fabrics and textiles. CNTs are also being used to make textiles stain resistant.

Catalyst Supports

CNTs intrinsically have an enormously high surface area; in fact, for SWNTs every atom is not just on a one surface – each atom is on two surfaces, the inside and outside of the nanotube! Combined with the ability to attach essentially any chemical species to their sidewalls (functionalization) provides an opportunity for unique catalyst supports. Their electrical conductivity may also be exploited in the search for new catalysts and catalytic behavior.

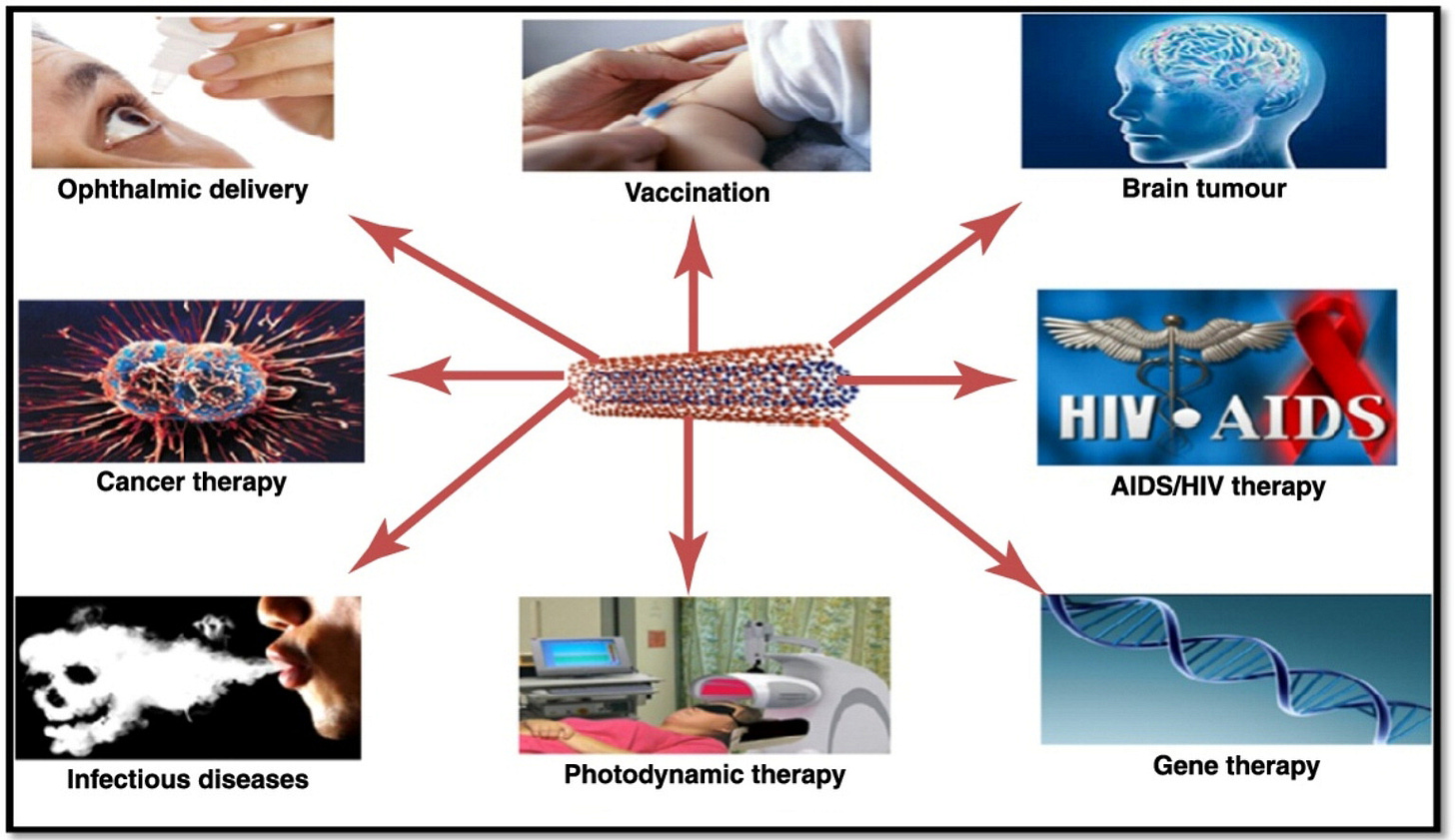

Biomedical

The exploration of CNTs in biomedical applications is just underway, but has significant potential. Since a large part of the human body consists of carbon, it is generally though of as a very biocompatible material.

Cells have been shown to grow on CNTs, so they appear to have no toxic effect. The cells also do not adhere to the CNTs, potentially giving rise to applications such as coatings for prosthetics, as well as anti-fouling coatings for ships.

The ability to functionalize (chemically modify) the sidewalls of CNTs also leads to biomedical applications such as vascular stents, and neuron growth and regeneration. It has also been shown that a single strand of DNA can be bonded to a nanotube, which can then be successfully inserted into a cell.

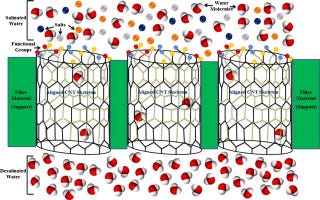

CNTs Air And Water Filtration

Many researchers and corporations have already developed CNT based air and water filtration devices. It has been reported that these filters can not only block the smallest particles but also kill most bacteria. This is another area where CNTs have already been commercialized and products are on the market now.

Conductive Plastics

Much of the history of plastics over the last half-century has involved their use as a replacement for metals. For structural applications, plastics have made tremendous headway, but not where electrical conductivity is required, because plastics are very good electrical insulators.

This deficiency is overcome by loading plastics up with conductive fillers, such as carbon black and larger graphite fibers (the ones used to make golf clubs and tennis rackets). The loading required to provide the necessary conductivity using conventional fillers is typically high, however, resulting in heavy parts, and more importantly, plastic parts whose structural properties are highly degraded.

It’s well-established that the higher the aspect ratio of filler particles, the lower the loading required needed to achieve a given level of conductivity. CNTs are ideal in this sense, since they have the highest aspect ratio of any carbon fiber. In addition, their natural tendency to form ropes provides inherently very long conductive pathways even at ultra-low loadings.

Applications that exploit this behavior of CNTs include EMI/RFI shielding composites; coatings for enclosures, gaskets, and other uses; electrostatic dissipation (ESD); and antistatic materials and (even transparent!) conductive coatings; and radar-absorbing materials for low-observable (“stealth”) applications.

Conductive Adhesives

Fujitsu Laboratories Ltd has announced the development of the world's first adhesive sheet composed of carbon nanotubes with extremely high thermal conductivity of up to 100 W/mK (watt per meter per Kelvin, the unit for measuring thermal conductivity).

The same properties that make CNTs attractive as conductive fillers for use in electromagnetic shielding, ESD materials, etc., make them attractive for electronics packaging and interconnection applications, such as adhesives, potting compounds, and coaxial cables and other types of connectors.

CNT Ceramic Materials

Carbon nanotubes can improve the electrical, thermal and mechanical properties of ceramic materials. Image Credits: Georgia Tech Research News

A ceramic material reinforced with carbon nanotubes has been made by materials scientists at UC Davis. The new material is far tougher than conventional ceramics, conducts electricity and can both conduct heat and act as a thermal barrier, depending on the orientation of the nanotubes.

Ceramic materials are very hard and resistant to heat and chemical attack, making them useful for applications such as coating turbine blades, but they are also very brittle. The researchers mixed powdered alumina (aluminum oxide) with 5 to 10 percent carbon nanotubes and a further 5 percent finely milled niobium. The researchers treated the mixture with an electrical pulse in a process called spark-plasma sintering. This process consolidates ceramic powders more quickly and at lower temperatures than conventional processes.

The new material has up to five times the fracture toughness — resistance to cracking under stress — of conventional alumina. The material shows electrical conductivity seven times that of previous ceramics made with nanotubes. It also has interesting thermal properties, conducting heat in one direction, along the alignment of the nanotubes, but reflecting heat at right angles to the nanotubes, making it an attractive material for thermal barrier coatings

Born in 2012, Scixel is a project devoted to the improvement of the scientific comunication through the creation of graphical products: pictures, animations, graphs, posters, etc. Scixel consists of scientists with a deep knowledge in digital graphics but also with a long experience in giving talks, preparing posters and papers and other daily situations of scientific work.

We have focused our work into universities and research institutes all over the world: TuDelft (The Netherlands), NIMS (Japan), Basel University (Switzerland), Universidad Autónoma de Madrid, CNB or ICFO (Spain), to name a few.

Web: https://scixel.es/

If you are a company or an individual who would like to place your advertising in my newsletter you can contact me (email) and let me know your request of type of ad and number of newsletters you would like to place it. I will send you a budget as soon as possible.